- by admin

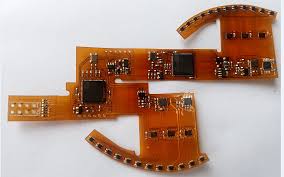

Flexible PCBs

The answer to this question depends on various factors such as the thickness of the circuit board, the material used for the dielectric layer, and the impedance characteristics. The maximum current and voltage, capacitance limitations, and bendability requirements should be considered to determine the right type of flexible PCB for your project.

There are several different types of flexible circuit boards, including single- and double-sided flex PCBs, multi-layer flexible PCBs, and rigid-flex circuits. Single-sided flex PCBs have a copper conductive layer combined with a dielectric material such as polyimide or polyester. Multi-layer flexible PCBs have a copper layer on each side of the dielectric material, and metalized holes are inserted to connect the two copper layers. Rigid-flex circuits are multi-layer flexible pcb that are stiffened using mechanical stiffeners, and are a good choice for high-speed applications where reliability is a priority.

When designing a flexible PCB, you need to consider its thickness, the materials used for the insulator and dielectric, and the impedance characteristics of the copper traces. The copper traces are the main components that provide electricity to all parts of the circuit board, so they must be designed to be able to handle the required current and voltage without exceeding capacity or causing damage. The design process starts with a schematic, which is a general representation and design of the circuit board. Then the PCB layout is created with a program such as Altium or Proteus, and the final board will be built from these drawings.

Flexible PCBs for Flexible Batteries

Another important factor to consider is the flexibility of your flex circuit board, and it can be determined by the minimum allowable bend radius. This is an important factor to take into account because it will influence the mechanical performance of your product. Moreover, it can help you avoid wasting materials and ensure the reliability of your product. This is important because the conditions in which your product will be used are likely to be harsh, and they may be exposed to a lot of heat, moisture, chemicals, shocks and vibrations.

Before the flexible circuit board is fabricated, it is essential to select the proper raw material and stack-up. This will impact the thickness, cost, and durability of the circuit board. In addition, you should also choose the type of coverlay and solder mask, stiffeners, and surface mount access openings. For example, photo imageable coverlay can provide complex openings for surface mount components and resistors with a variety of shapes and sizes.

It is also important to review the reference plane layers and shielding for the flex circuit, which can affect impedance control and signal integrity. For instance, solid copper increases the rigidity of the flex PCB and should be reviewed in relation to the thickness-to-bend radius. Furthermore, shielding methods can help protect the signals by preventing interference from external sources. In addition, it is crucial to add labels, identifiers, markings and reference designators to the PCBs before production. This will save time and effort during assembly.

Flexible PCBs are extensively used in LED lighting applications due to their ability to conform to curved surfaces. They are employed in flexible LED strips, backlighting for displays, automotive lighting, and architectural lighting. Flexible PCBs enable innovative lighting designs and energy-efficient solutions.